Bodens Energi AB is a municipally owned combined heat and power company with 93 employees. The company delivers electricity and district heating to the residents of Boden and surrounding areas. Since September 2019, Bodens Energi has been working with Sigholm Tech AB to develop their maintenance operations.

Emergency Call-outs Due to Insufficient Maintenance

During 2019, Bodens Energi underwent reorganisation and wanted to take the opportunity to develop their maintenance work processes. They identified potential improvements in work processes related to district heating maintenance, both in terms of structure, standardisation, information flow and communication. Emergency call-outs dominated daily operations and often pushed aside long-term planning and preventive maintenance, work that in many cases could have prevented the emergency faults that occurred. Additionally, tthey wanted to implement a more uniform approach to their maintenance system, as operating procedures varied and could differ between individuals and departments.

Implementation of New Work Process and Training

To address this, Sigholm, together with Bodens Energi, developed new work processes tailored to operational needs and implemented them. The processes encompassed both preventive and corrective maintenance procedures, including system adaptations and staff training in operating procedures and system usage. Additionally, training and tools were developed for continuous improvement and storage management. After implementation and training, Sigholm was given continued trust to actively revise and adapt operating procedures in close cooperation with Bodens Energi to further establish the new methods. The overall goal of clear and standardised processes is for all employees to understand expectations and work towards the same goals. "Change that originates from within the organisation is key to ensuring its acceptance and sustainability. This is why working closely with the staff directly affected by these changes is crucial," says Malin Rådberg, business developer at Sigholm on site in Boden.

”Change that originates from within the organisation is key to ensuring its acceptance and sustainability. This is why working closely with the staff directly affected by these changes is crucial," says Malin Rådberg, business developer at Sigholm on site in Boden.

Measurable Success After Adapted Maintenance System

The employees at Bodens Energi have a strong and positive willingness to change and quickly adopted the new operating procedures. Thanks to increased utilisation of the maintenance system, the amount of reliable data in the system is increasing, which in turn improves traceability and the ability to analyse and work preventively with maintenance work.

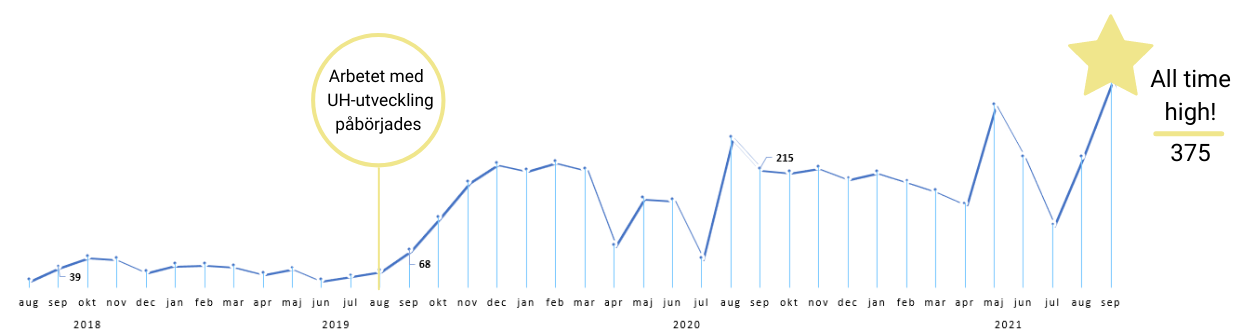

After more than 2 years of cooperation, we can now measure success in various ways, including seeing a continuous increase in the number of completed work orders per month in the maintenance system. This means that the jobs performed now enter as statistics in the maintenance system and thus contribute to an increased understanding of the plant. The statistics can also be used as support for investments and strategic initiatives at Bodens Energi.

The graph shows how the number of completed work orders per month has changed over time, where we can see a clear change in August 2019 when targeted work began focusing on processes and systems to support maintenance work. We can also see that despite months with downturns, the minimum level is continuously rising, which in itself is a measure of improved documentation of completed jobs in the facility.